Blog >> Automatic Slotting and Creasing Machine for Corrugated

slotting and creasing machine for corrugated box

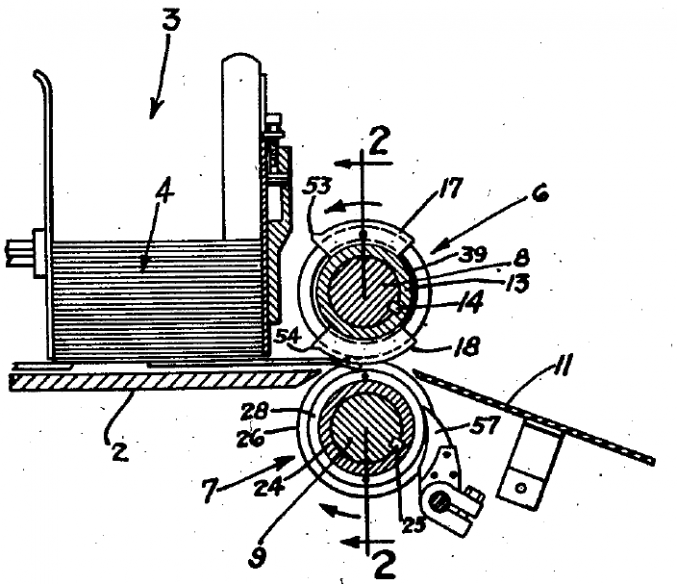

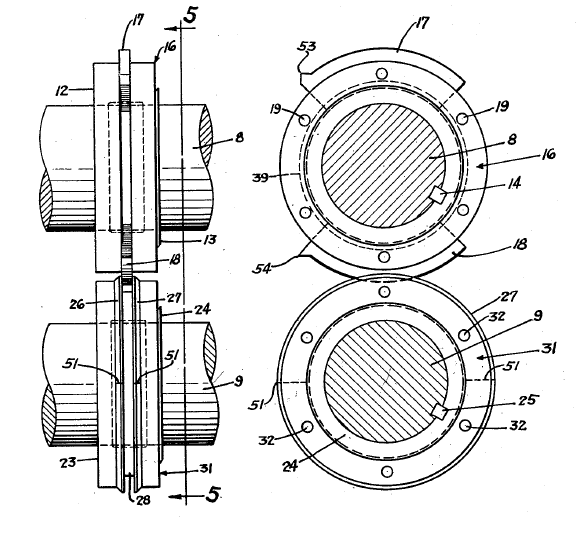

To define the panels in a blank of corrugated paper or board that will make up into a corrugated container when set up, the blanks hereto fore have been provided with both single and double creases. Single crease have not been desirable, because when the panels or sections of the blank are folded upon themselves to what is commonly referred to by the trade as a complete one hundred eighty degree fold, too great a strain is exerted on the outside face or surface of the blank which may fracture the paper, except when using the best kraft-lined corrugated board. Double creases are therefore generally utilized, when a portion of the blank is to be folded to one hundred eighty degrees, such as when collapsing a partially completed box for storage purposes. When double creasing a blank with conventional equipment, as is now common in the art, no provision has heretofore been made to limit the fold at each crease to ninety degrees, and the result has often been “lopsided” and uneven folding of the blank, which frequently has been so bad where the creases are disposed substantially parallel to the corrugations, that the blank could not be folded and taped by automatic machinery and obtain a uniform product which .would be acceptable to the trade. One of the features of the present invention resides in the construction of such a machine wherein but a single pair of slotting and creasing heads are utilized, said heads being provided with combined slotting and creasing dies, whereby as each blank is fed between said heads, the required slots and creases are formed therein in a single operation and with the assurance that said slots and creases will be accurately disposed with respect to one another. It is therefore the primary object of the present invention to provide not‘only a novel combined cutting and creasing member or die, but to so shape the pair of cutting and creasing members that when the blank has been creased and is subsequently folded over upon itself along adjacent creases, each crease will limit the paper to be bent but ninety degrees, whereby adjacent creases will permit the blank to be folded to a complete one hundred eighty degrees bend or fold, the shaping of the creases by the creasing members being such that the opposed walls of each crease will contact each other and thus limit the corrugated board to a ninety degree bend at each crease, thereby resulting in accurate folding of the blank panels so that when the opposed ends of the blank are secured together by suit able means, such as a binding tape, the walls of the partially completed carton or box may be collapsed into parallel relation to facilitate storage, and with the assurance that the walls at the corners of the collapsed carton or box will not be subjected to excessive strain because of double folds.

A further object is to provide in a box making machine a single pair of complemental cutting and creasing-heads, one of said heads having combined cutting and creasing members removably mounted thereon, and, the other having means mounted thereon adapted to co-act with said combined cutting and creasing members to slot and crease each blank as it is fed between. the heads.

slotting heads in slotting and creasing machine

Other objects of the invention reside in the simplified construction of the cutting and creasing members and in the manner in which they are removably supported on the head; in the means for securing the slotting knives in the other of said heads and whereby one of said knives is circumferentially adjustable with respect to the other and without requiring its removal from the head; in the provision of a pair of opposed creasing members having their in wardly facing peripheral corners providing cut ting edges, and the outwardly facing peripheral corners of said members being beveled at such an angle that the combined angles-of said beveled faces is less than ninety degrees, thereby to cause the inclined walls of each crease to firmly con tact each other- when the blank is bent therealong, whereby the resultant‘ corner of the box will be substantially right-angular in configuration, as there will be no “slack” o‘r “looseness” in the bend ‘ or fold; and in the simplified construction of the creasing members and cutting knives, where . by they may be readily removed for sharpening or repairs, if necessary, and also whereby one set of dies or knives may be quickly substituted for another, should it be’ deemed advisable to change to narrower or wider dies and knives for a given job. Other objects of the invention will appear ‘from the following description and’ the accompanying drawings and will be pointed out in the annexed claims.

In the accompanying drawings there has been disclosed a structure designed to carry out the various objects of the invention, but it is to be understood that the invention is not confined to the exact features shown, as various changes ‘may be made within the scope of the claims which follow.

SinoCorrugated Exhibiton is the biggest and most important exhibiton for corrugated carton flexo pri...

In 1989s, China begin reform and opening, there exist mostly state-owned factories before that. Aft...

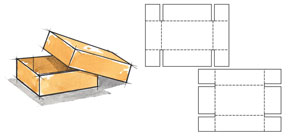

Corrugated Box Making Machine and ProcessAs used herein and as well understood in the industry, corr...

What are the types of corrugated boxes which are used in industries?The factors that are considered ...

Corrugated boxes are made from corrugated paper which is glued to the flat facing of a flat paper ma...