Blog >> Corrugated Box Making Machine and Process

Corrugated Box Making Machine and Process

As used herein and as well understood in the industry, corrugated stock refers to a paper product that is also commonly (but somewhat erroneously) referred to as “cardboard.” More properly, corrugated board is formed from one or more pieces of “fluted” paper, a term that describes paper that has been crimped into a somewhat sinusoidal cross section by an appropriate fluting machine-single facer. One or more layers of flat paper typically referred to as “liners” are glued to the fluted layer. Accordingly, many corrugated boxes (as well as corrugated packing inserts and similar structures) are formed of inner and outer liner sheets, with one or more fluting layers in between, and with at least one liner between each fluting layer.

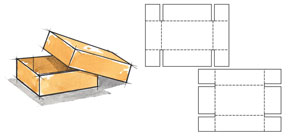

Because corrugated board is typically formed in long running sheets, it must be cut and folded to form boxes by slitting and scoring machine. Typically, the corrugated board (which can be referred to as a “blank”) is first cut and creased to define the portions that will eventually be folded. The blank is then partially folded and a glue strip is applied to one side to fasten it to an overlapping side. The resulting structure is a flattened parallelogram of corrugated board containing cuts and creases that will later define the sides and flaps of the box, and thus its eventual solid rectangular shape. The folding and gluing operation is usually automated, and carried out by a machine referred to as a “folder-gluer.” Aprinting step is often carried out on the blanks at some point in this process. Because the present invention does not generally relate to printing boxes, the specific details of printing will not be discussed in any further detail herein. Boxes are, however, typically printed, folded, and glued one at a time. Because corrugated boxes are often used in large volumes, these individual fattened boxes must be collected, counted, bundled, and stacked into loads for eventual shipment to an end user, typically in the fattened condition.

Because flattened and glued boxes are so often shipped in large numbers to their end users, they likewise frequently travel in trucks and containers (“container” refers to the widely used metal containers that are approximately the size of a truck trailer, and are often carried as such, but that are also designed to be carried by ships and on railroad cars). when boxes are shipped in this fashion, they are typically stacked into loads that at efficiently inside a truck or a container. Such loads are frequently about 45 “ wide because two such loads at comfortably inside a truck or a container in side-by-side relationship.

Conventionally, the individual folded glued boxes are either automatically stacked on a one-by-one basis or stacked in bundles using a manual technique. Because of their one-by-one nature, such techniques can represent the slow point in an overall box production process. As a result, the counting, bundling, stacking, and load-forming steps often represent the rate-limiting steps in a box production facility. Additionally, the conventional counting and stacking techniques do little to enhance the integrity of the fresh glue joint and in many cases can even weaken the glue joint, thus weakening or even ruining the resulting boxes.

Accordingly, the need exists for an apparatus and associated technique for receiving, counting, bundling, stacking, and forming loads from folded glued box blanks that is as fast as the production and printing steps of the process. Furthermore, because the boxes are most preferably prepared for loading without delay following their manufacture, the process should avoid damaging the glue strip, and a need exists for processes which will enhance the glued structure rather than place stress upon it.

SinoCorrugated Exhibiton is the biggest and most important exhibiton for corrugated carton flexo pri...

In 1989s, China begin reform and opening, there exist mostly state-owned factories before that. Aft...

Corrugated Box Making Machine and ProcessAs used herein and as well understood in the industry, corr...

What are the types of corrugated boxes which are used in industries?The factors that are considered ...

Corrugated boxes are made from corrugated paper which is glued to the flat facing of a flat paper ma...