Products >> Automatic Flexo Printing Machine for Corrugated Cardboard >> Flexo Printer Slotter Folder for Corrugated Carton Box

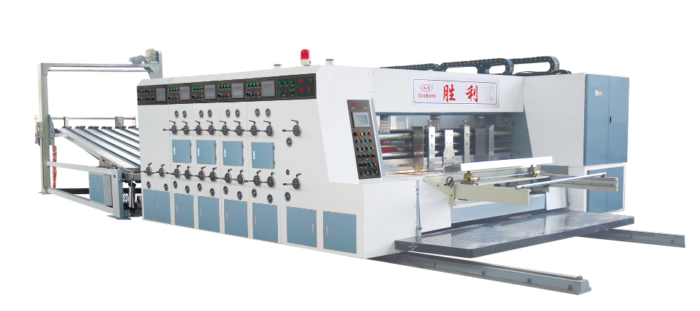

Flexo Printer Slotter Folder for Corrugated Carton Box

If the container design is more complex-requiring slots in both directions, at many different places and at angles to the edges of the sheets or requiring punch-out windows-the container must be cut differently, a corrugated box die cutter uses a curved die cutting plate, with sharp knives and dull scoring blades extending from its surface. The rotary die cutting machine for corrugated carton may also have attached or in-line printing stations to allow blank sheets to be printed and die cut in one pass. The blanks still require folding and sealing in a separate operation. Depending on the complexity of the folding operation, the folding may be done in a machine or manually, as in the case of store display stands.

Printer-slotter-folders for corrugated box have become quite complex and sophisticated. Sheets from the corrugator machine are loaded into one end and finished containers are delivered to skids and perhaps even wrapped and sealed for shipment on the other end. The streamlined, efficient operation of flexo printing slotting folding machine makes it the preferred box making machine, and the most profitable to operate. Designs are fairly flexible, but still limited to scoring and tab-cutting in the direction of the flutes, or perpendicular to the score made on the corrugator.

Flexo printing is accomplished with flexo presses using water-based inks. The press may print up to four colors, although most are equipped for only two or three. The brown color of the container is not well suited to four-color printing, but by properly selecting the colors, some interesting graphics can be created. The flexo plates are stapled to a wooden printing plate cylinder, and can be changed rapidly when jobs are changed. The ink is pumped up to the printing unit from a 5-gal pail set on the floor next to the machine and can also be changed rapidly. The flexo printers use the anilox roll modification and are capable of halftones of fairly good quality. The use of flexo allows the plate to be pressed against the board, conforming to its rough surface, with little danger of crushing the flutes.

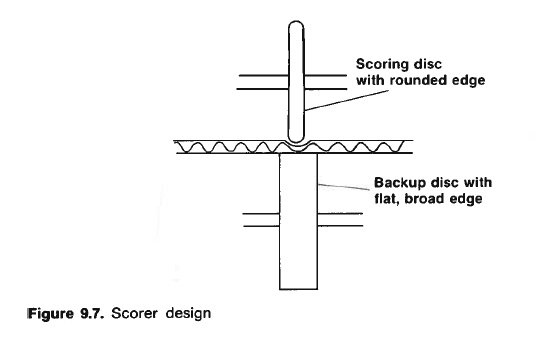

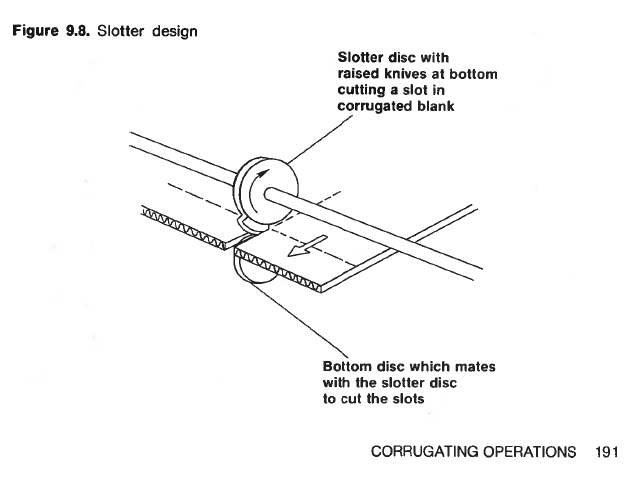

The slitter scorer section has recently gone through a major advance in automated setup to allow faster changeover from one order to another. The scorers are dull discs attached to a shaft above the board, as shown in figure 9.7,and the slotters are U-shaped dies, which also are attached to a shaft above the board, as shown in figure 9.8.

The slotter and scorer need to be positioned at the right places from side to side on the machine, and the slotters also have to be placed at the proper location with respect to the horizontal travel of the blank through the machine, the positioning is a slow, critical and painstaking task to accomplish by hand. The operator must individually measure and set all slotters and scorers in what is believed to be the right place.

slotting and scoring blade position

A few sample blanks are then sent through,measured and the settings corrected if needed. The newer machines are equipped with servo-motors that can position the scorers and cutters automatically. The position of each device can be dialed in or fed to the controller by card, the devices automatically positioned and the sample blanks run. It may still be necessary to make minor adjustments, but they also can be dialed in and made by the servo-motors. Since most plants operate on small orders requiring frequent changes and must deliver in a hurry, these advances are most helpful.

The printed, scored and slotted blank is now ready to be folded and glued. The adhesive is normally a latex type, which can be applied by rollers or more frequently, sprayed onto the tabs as they pass through the machine and under the spray heads. The positioning and timing of the spray are adjustable and can be automated. The tabs are folded and pressed into position by metal tabs and rollers. The folded container is generally fed between belts, where it’s held closed briefly, allowing the adhesive to set. The container is also fed to a stacker, which keeps it closed until it can be loaded on the skid. More advanced machines collect, count and position the stacks on the skid and prepare the skid for banding, wrapping and shipping.

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...