Products >> Automatic Flexo Printing Machine for Corrugated Cardboard >> GYK-A Flexo Printing Machine -140 Pics/min

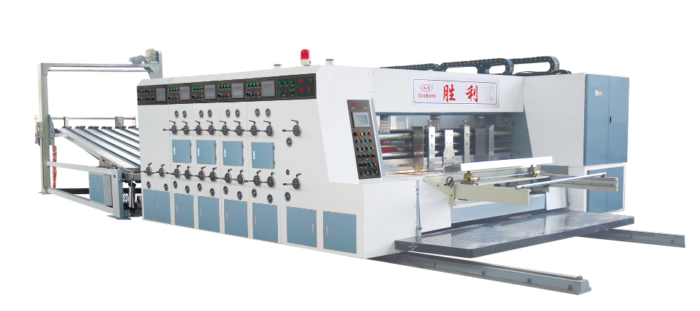

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/min

GYK-A is improved model of YFQ flexo printer with chain feeder, GYK-A adopt electric control system and the slotting baldes and lead edge feeder is controlled by pressing buttons.

Whole machine characteristics

1) Low voltage electric parts adopt domestic famous brand parts.

2) Main parts bearings adopt domestic famous brand LYC, ZWZ and Harbin

3) Main gears adopt high frequency quenching processing to ensure high precision transmission.

| NO. | Parametre | Unit | GYK-A1370X2200 | GYK-A1370X2500 | GYK-A1370X2800 |

|---|---|---|---|---|---|

| 1 | Design speed | Pcs/min | 100 kick back 140 lead edge | 100 kick back 140 lead edge | 100 kick back 140 lead edge |

| 2 | Width of inside machine | mm | 2400 | 2700 | 3000 |

| 3 | Max feeding paperboard size | mm | 1300×2200 | 1300×2500 | 1300×2800 |

| 4 | Min feeding paperboard size | mm | 400×700 | 400×700 | 400×700 |

| 5 | Feeding paper by skip | mm | 1600×2200 | 1600×2500 | 1600×2800 |

| 6 | Max printing area | mm | 1300X2040 | 1300X2340 | 1300X2640 |

| 7 | Over printing precision(2/3/4color) | mm | ± 0.5/ ± 0.75/ ± 1.0 | ± 0.5/ ± 0.75/ ± 1.0 | ± 0.5/ ± 0.75/ ± 1.0 |

| 8 | Printing plate standard thickness | mm | 6 | 6 | 6 |

| 9 | Printing paperboard thickness | mm | 3–11 | 3–11 | 3–11 |

| 10 | Printing roller axle circular adjust | degree | 360 ° | 360 ° | 360 ° |

| 11 | Printing roller axial adjust | mm | ± 10 | ± 10 | ± 10 |

| 12 | Max slotting space | mm | 190x50x190x50 | 190x50x190x50 | 190x50x190x50 |

| 13 | Max slotting depth | mm | 340 | 340 | 340 |

| 14 | Max die cutting size | mm | 1300×2100 | 1300×2400 | 1300×2700 |

| 15 | Die cutting thickness | mm | 3–8 | 3–8 | 3–8 |

| 16 | Total power(2/3/4 color) | Kw | 19/22/27 | 19/22/27 | 19/22/27 |

| 17 | Two color | mm | 7000x4000x2400 | 7000x4000x2400 | 7000x4000x2400 |

| 18 | Three color | mm | 7500x4500x2400 | 7500x4500x2400 | 7500x4500x2400 |

| 19 | Four color | mm | 8000*5000*2400 | 8000*5000*2400 | 8000*5000*2400 |

| 20 | Total weight of machine (double/three/four colors) | ton | 16/19/22 | 19/22/25 | 22/25/28 |

Lead edge feeding paper device can decrease the blocking phenomenon when feeding paper.

It adopt air blower auxiliary feeding paper , the bending paper can feed in smoothly.

Wind volume can adjust according to the paperboard size , so it can make the adsorptive power at the maxi level and feed paper precisely.

Side baffles adopt electric adjustment , front and back baffle adopt manual adjustment.

Feeding paper wheel adopts PU material , strong friction and long using life.

Feeding paper by partition device , it can choose feed paper by partition or continuation.

It is used to three , five layer paperboard also including E flute paperboard.

it install counting device , it can set and display production number.

2. Printing unit

The printing roller surface is chromed and polishing and with dynamic balance , it makes the roller run steadily.

Even ink roller surface is packed with wear resisting rubber , the middle of the rubber is a little high and the parabola shape to compensate the stress deformation and improve the even ink effect. The rubber is NBR , the hardness JIS is more than 60°, it has gone through special polishing , the even ink effect is good , the rubber roller adopts reducing speed motor to drive when the main motor stops , it will also run.

The machine anilox roller adopt HAILI WUJIN JIANGSU product , it owns mature technology to produce the meta anilox roller , the cylinder is less than 0.016mm, the radial run out is less than 0.1mm , it use 25 times the magnifying glass to check the anilox roller , the surface is clear , bright and clean , the hardness can reach HV900—1050, so it owns good storage ink , even ink and transmit ink function , it is the best choice for the printing and good guarantee the anilox roller diameter is 187mm.

Electric phase adjusting structure , it can achieve 360 degrees adjustment both it runs and stops , it can save adjusting time and improve the working efficiency.

The printing ink supply system adopts pneumatic diaphragm , steady supply , easy operation , it is the domestic famous brand.

It adopts pneumatic lifting board device , auto even ink device , so when the machine stops the ink will not be dry and influence the printing effect.

The whole machine adopts spray lubrication , it can decrease the machine noise and improve the gear using life.

3. Slotting unit

The pressing line wheel surface is chromed , moves smoothly , it is equipped with four sets pressing line wheel , the pressing wheel gap adopts manual adjustment with dial shows the data , the adjusting range is 0-11mm.

The slotting phase adopts planet type gear structure and electric digital 360 degrees to adjust(working or not working)

The slotting knife axle surface is grinding and chromed , moves smoothly , the up slotting knife material adopts alloy steel with heat treatment and sharping, the shape is saw tooth , the hardness is HRC60-63, good toughness , the up slotting knife is 7mm , the down slotting knife adopts alloy steel and heat treatment and grinding , the trimming knife and slotting knife material is the same , it has gone through heat treatment and grinding with two part , the knife is sharp.

The whole machine adopts spray lubrication , it can decrease the machine noise and improve the gear using life.

It is equipped with the synchronous adjusting knife , it can decrease adjusting time of adjusting the carton box height and improve the working efficiency.

4. Die cutting unit

Surface of the roller is hard chromed , the roller has gone through the dynamic revise so it can increase its steady and reliability when it revolving.

The gap between cutter mould roller and cushion roller adopt manual adjustment

The die cutter phase adopt planet type gear structure , high precision ,can bear big load strength . It can adjust the phase within 360 degrees when the machine revolving or stopping.

When stopping feeding paper , the cushion roller will rise up automatically so it can decrease the cushion roller attrition.

The cushion roller adopt the Polyurethane felt (super resisting brand) , it can achieve the 100% cut off rate , the edge is smooth , the exchange order should be according to the operating handbook.

The cushion roller adopt mechanical cam facility move ,the range is 40mm , so it will not cut the same place all the time and prolong the cushion roller using life.

The cutter mold roller can adjust the lateral distance within ±10mmwith manual adjustment.

Diameter of cushion roller and cut mold roller is different , but their linear velocity is same , it can control the cutter knife will not cut the same place , the working track of knife is infinite and not cycle , so the cushion roller can be abrade more even.

The linear velocity compensate device , when the cushion roller diameter changes ,the compensate device can automatically track and compensate without the manual Adjustment so it ensure the same size of the carton box and prolong the using life of the cushion and cutter mould roller.

The cushion automatic repairing device can repair the cushion some times , after repairing , the cushion is smooth and it possess the same function with the new , so it improve the repeat using rate of the rubber.

5. Stacking Unit

The receiving paper arm adopt auto and manual operation with safe structure to avoid receiving paper arm suddenly drop and hurt operator.

The convey paperboard plate adopt powerful chain drive.

The height of stack is 1600mm.

With the paperboard stacker height changing, the platform automatically adjusts the gradient height, Lifting motor is with the brake function, then the convey paperboard plate can keep the fixed position to prevent falling down.

The pneumatic supporting paperboard structure, when reach the setting height, the supporting paperboard device will automatically open, then adopt other device to support paperboard.

6.The corrugated belt can prevent the sliding of the paperboard.

Transmission gear

The printing roller adopt high wear resisting nodular alloy cast iron (QT600-3), other

gears adopts 45# carbon steel and quenching tempering treatment. The whole machine

adopts spray lubrication , it can decrease the noise and prolong the using life.

Hebei Shengli Carton Equipment Manufacturing Co.,Ltd is one of the largest Corrugated Carton & Box Making Converting Printing Machines Equipments manufacturers in China, supply high quality machines and good service for corrugated box plants wordwidely. We are specialized at corrugated box carton & cardboard machines . Corrugated sheet making machine, corrugated sheet cutter, boardcard slitter, flexo printing press, box folder & gluer, corrugated cardboard die-cutting machines. Anything you have interested, please contact me : corrugatedboxmachine@hotmail.com

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...