Products >> Corrugated Cardboard Porduction Line >> Single facer in Corrugated Board Making Line

The positon of single facer in Corrugated line

The first part of the corrugating machine is known as the single facer, since it’s here that the medium is fluted and attached to the top liner,making single face board.

The operation can be divided into four basic sub-operations:

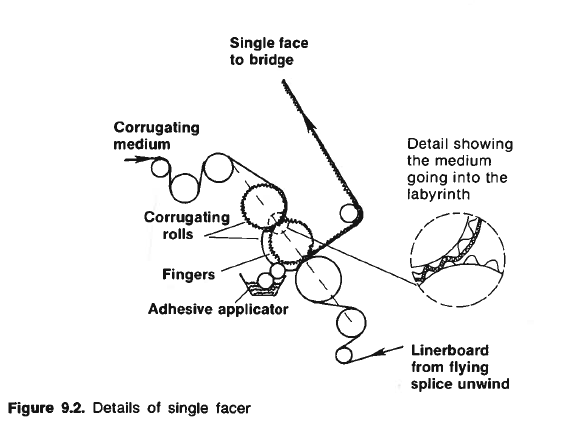

The drawing in figure 9.2 shows the medium being supplied from an unwind,which is under the part of the machine known as the bridge.The top liner is unwound from a position at the outside of the unwind/rewind roll stands. The unwind stands are generally turret unwinds, which allow the use of flying splices so that the rolls can be changed without stopping the machine.

Both webs maybe passed around heated drums to heat them before combining. Steam may also be used,especially on the medium to increase its flexibility. If the two webs are at greatly different temperatures or moisture contents before combining, the resultant structure will likely curl.

Primary responsibility for the moisture content lies with the manufacturer of the webs but small adjustments can be made on the machine.The web to be corrugated is passed between two rolls with corrugated surfaces or inter meshing teeth all across their surface, which force the web into the fluted shape. The web must be made to hold this shape after it passes form these two rolls and the contorted space between them,called the labyrinth. As it enters the labyrinth, the web is sprayed with steam to heat and moisten it to make it more pliable. The corrugating rolls are heated to dry the web and make it hold its shape. The inclusion of wax and starch in the steam shower is purported to improve release from the rolls and help to stiffen the medium.

As the corrugated web passes from the labyrinth, it’s held against one of the two rolls by a series of thin steel pates called fingers. Between these fingers is a set of rollers used to apply adhesive to the tops of the flutes. Before the fluted medium and the adhesive leave the corrugating roll, the top liner is pressed against the glued surfaces. The adhesive is a starch solution of the proper solids and composition to become sufficiently tacky in this short time to hold the two webs together as they pass up to the bridge. This adhesive is generally a mixture if starch granules and pasted or cooked starch in which the granules have been broken down. Higher levels of water resistance require a latex type adhesive and a top liner to which wet-strength resins have been added. As was boated earlier, the board is taken up to the bridge, where it’s stored to give the adhesives time to dry and form a permanent bond.

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...