Blog >> Pulping and stock preparation of primary fibres

The wood chips are normally cooked to pulp for Kraftliner production by the kraft cooking process. It is a highly alkaline cooking process with caustic soda and sodium sulphide as active cooking chemicals. The cooking takes place in a digester at high pressure and a temperature of 150 -170 oC. The pulp yield is normally around 55% i.e. 1000 kg of dry wood gives 550 kg of pulp. For Fluting production the wood chips are cooked to pulp by the Semichemical cooking process. It is a slightly alkaline cooking process most commonly with sodium sulphite and sodium carbonate as active cooking chemicals.

Pulping and stock preparation of primary fibres

The pulp yield is normally around 80%. The spent cooking liquor is drained off and washed out from the pulp. It contains the wood substance dissolved during the cooking together with the spent cooking chemicals. The spent liquor is concentrated and burnt for steam production and recovery of cooking chemicals.

The pulp produced is defiberized in refiners, screened and washed before being sent to the paper mill. In the paper mill the pulp is mechanically treated in beaters to improve fibre-to-fibre bonding and strength of the paper. The pH level of the pulp slurry is adjusted with acid and some additives are added to facilitate the paper production. Functional chemicals, fillers and other pulps i.e. recovered paper pulp may also be added to give the final paper the properties required. Finally the pulp slurry is screened and diluted before being sent to the head box of the paper machine.

SinoCorrugated Exhibiton is the biggest and most important exhibiton for corrugated carton flexo pri...

In 1989s, China begin reform and opening, there exist mostly state-owned factories before that. Aft...

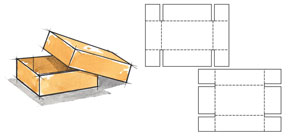

Corrugated Box Making Machine and ProcessAs used herein and as well understood in the industry, corr...

What are the types of corrugated boxes which are used in industries?The factors that are considered ...

Corrugated boxes are made from corrugated paper which is glued to the flat facing of a flat paper ma...