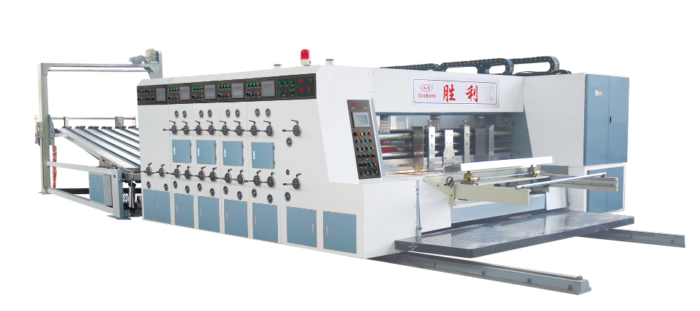

Products >> Automatic Flexo Printing Machine for Corrugated Cardboard >> QYMW High Definition Flexo Printer-180 Pics/min

The QYKM series of high speed flexo ink corrugated cardboard printing, slotting, die cutting machine is designed for high precision printing with a max DPI of 500-600. These models of printing machine for intended for high quality printing operations with lower speed requirements with a 180pcs/min output. This flexo printer slotter die cutter comes in 6 different color options.

| No. | ParameterName | Unit | QYMW1270*2200 | QYMW1270*2500 | QYMW1270*2800 |

|---|---|---|---|---|---|

| 1 | Width of inside machine | mm | 2400 | 2700 | 3000 |

| 2 | Design Speed | pieces/min | 180 | 180 | 180 |

| 3 | Nax feeding size | mm | 1200*2200 | 1200*2700 | 1200*2800 |

| 4 | min feeding size | mm | 400*700 | 400*700 | 400*700 |

| 5 | skip feeding | mm | 1600*2200 | 1600*2500 | 1600*2800 |

| 6 | max printing area | mm | 1150*1850 | 1150*2150 | 1150*2450 |

| 7 | precision of precess printing(five color) | mm | ±0.5 | ±0.5 | ±0.5 |

| 8 | thickness of standard printing blank | mm | 7.2 | 7.2 | 7.2 |

| 9 | thickness of printing paperboard | mm | 3–11 | 3–11 | 3–11 |

| 10 | printing roller axle circle-oriented regulating | degree | 360°运转 revolving | 360°运转 revolving | 360°运转 revolving |

| 11 | printing roller axle oriented regulating | mm | ±10 | ±10 | ±10 |

| 12 | max die cutting size | mm | 1200*2150 | 1200*2450 | 1200*2750 |

| 13 | die cutter thickness | mm | 3–8 | 3–8 | 3–8 |

| 14 | die cutter precision | mm | ±1 | ±1 | ±1 |

| 15 | total power(four/five/six color) | kw | 178/190/202 | 178/190/202 | 178/190/202 |

| 16 | Four Color | mm | 9000*4600*3060 | 9000*4900*3060 | 9000*5200*3060 |

| Five Color | mm | 9600*4600*3060 | 9600*4900*3060 | 9600*5200*3060 | |

| Six Color | mm | 10200*4600*3060 | 10200*4900*3060 | 10200*5200*3060 |

2.Lead edge feeding unit

Adopt triplex row feeding wheel , three groups Germany “REXROTH” servo system,separate drive , non-gear box wear , long life , high precision. Back shield up and down , moving is electric , adjusting easy and accuracy .Adopt double row feeding ,large tension ,make sure the large size carton printing with skip feeding suction and return to zero device. The host adopt synchronous belt transmission, transmission balance, can absorb vibration, low noise, economic operation, etc

1) Servo auto feeder allows for free pressing feeding.

2) Touch screen interface to show and operate the machine with PLC to communicate with other units.

3) Equipped with an absorption vacuum auxiliary system to ensure a smooth paper feed.

4) Equipped with a counting device and a protective motor starting unit.

5) Electric adjustment of the front, back, left and right baffle.

3. Printing unit

The table space with electric adjustment, PLC control digital display, the feed rollers with new ceramic grinding process, minimal wear, friction, long life;platen roller adopts a seal between the baffle to ensure the vacuum pressure between the units and the shaft attached to the electromagnetic clutch brake mechanism;Work table adopt high pressure centrifugal fan, by the inverter to control the size of the wind, the bellows damper size can be automatically controlled to achieve the role of trace amounts of correction; Printing roll through dynamic and static balance correction, hard chrome plating and grinding;Roller tracking stopper double protection, sliding with electric adjustment, and an automatic return of function; Ink with automatic leveling, automatic leveling shutdown ink to prevent ink drying affect print quality; Scraper system used by the Sun’s color master single blade system;The two-way pneumatic diaphragm pumps, ink supply amount is controlled by PLC, automatic cleaning cycle and ink

1) Vacuum type paper feeding unit.

2) The printing phase is servo controlled with a ceramic feeding wheel, featuring a long useful life.Steady vacuum paperboard feed with no need for auxiliary pulling paper cushion.

3) Color doctor blade designed by SUN Automation allows for more clear and high quality printing effects.The printing plate roller pahse and lateral adjustment are electrically controlled by PLC.

4)ColorMaster Single Blade System from Sun Automation.Each anilox roller is integrated with one set of Colormaster single blade system, which ensures that only ink in the cells is transferred to the plant, achieving the high-definition graphic printing.

Independent drying system adopts infrared mode, fast drying water-based ink printing surface to avoid the phenomenon out of ink. The drying area is divided into three sections, adjustable range, energy conservation. Electrically adjustment clearance table and drying system. Ultraviolet drying unit is optional for water-based ink and UV oil ink, avoid dragging phenomenon when die cutting.

1) Smooth paperboard delivery via vacuum transmission.

2) Quickly heats paperboard after printing to improve machine speed and printing quality.

3) The heating unit prevents dust from the slotting and die cutting enter into printing unit.

4) Infrared and ultraviolet drying methods available to choose from.

Adopt separate double servo drive, make sure synchronous with printing unit. The paper guide roller and lower shaft gap adopt two-way self-locking device, digital display; Die board roller is controlled by independent servo roll (excellent roller pads) may at any time amend. Die rolls from Germany “Rexroth” servo motor control, reducing the transmission link error; The phase adjustment device directly by the servo motor, the exact place.

Bin arm using pneumatic operation, manual control; The bed platform lift, strong chain drive, the drive motor attached to the brake function; Stacking is equipped with a flat wrinkles climbing belt and steel clamping device, so that the stacking order and tidy with pneumatic anti decline devices to ensure operator safety; Hold paper feeder can be adjusted to hold the opening width, with a batch accumulation function; The use of side shoot baffles to ensure more orderly stacked cardboard; Electric enforce the use of PLC programming control, independent of the operating electric box; The device is equipped with a lateral row of wast.

1) Platform rises up and down with safety features to protect the operator.

2) Frequency conversion adjustment of the speed drive.

3) The receiving paper belt adopts vacuum absorption transmission neatly stack the paperboard.

4) Fan and brush work together to clear scraps from the slotting unit and die cutting unit.

Hebei Shengli Carton Equipment Manufacturing Co.,Ltd is one of the largest Corrugated Carton & Box Making Converting Printing Machines Equipments manufacturers in China, supply high quality machines and good service for corrugated box plants wordwidely. We are specialized at corrugated box carton & cardboard machines . Corrugated sheet making machine, corrugated sheet cutter, boardcard slitter, flexo printing press, box folder & gluer, corrugated cardboard die-cutting machines. Anything you have interested, please contact me : corrugatedboxmachine@hotmail.com

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...