Products >> Automatic Flexo Printing Machine for Corrugated Cardboard >> YFQ Chain Feeder Flexo Printing Machine

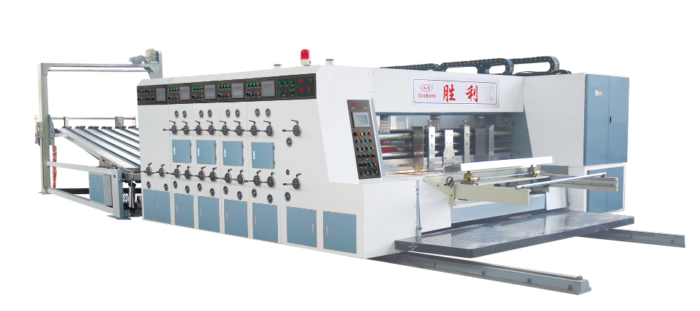

YFQ Chain Feeder Flexo Printing Machine with Slotter

3. YFQ series printing machine function and characteristics

1.Adopt electric separation , automatic lock.

2.The pneumatic brake , it can ensure the original adjusting size not changing.

3.Adopt the brush to clear the dust on the paperboard and improve the printing quality.

4.Adopt pneumatic lift board , automatic leading ink device and when the machine stops ,

5.the ink can still run , so it can avoid the ink come into dry when the machine stops and

6.eliminate the printing effect disadvantage factor. (not including air pump)

7.Adopt the diaphragm pump , the operator can adjust the ink quantity according to the needs.

8.and improve the leading ink effect.

9.Adopt electric counter , it can control the paperboard quantity rightly.

10.Adopt the alarm bells device , when the machine start , the alarm rings to remind the

11.operator warning.

12.It is equipped with the synchronous adjusting knife device, so it decrease the adjusting carton box height and improve the production efficiency.

13.It is equipped with the electric adjusting phase device , so it can adjust the printing phase with 360 degrees and the slicing corner position when the machine stopping and running . It can save the source and improve the production efficiency.

14.It is equipped with the printing plate phase numerical display device , so the operator can adjust the phase by numerical control adjustment .

15.It is equipped with the electric adjusting phase device , the operator can adjust the printing plate within 360 degrees no matter the machine running or stopping. It is not only saving the time but also improve the production efficiency.

16.Adopt the spray lubrication , it can decrease the running noise and improve the gear using life.

4.Introduction of each unit of YFQ Printing Machine

1.Feeding unit

1) Chain feeding

2) Speed adjustment table for indication and operation.

2.Printing unit

1) Metal anilox roller with optional ceramic roller upgrade.

2) High quality rubber roller.

3) Touch screen interface to perform phase adjustments and other operating procedures.

3.Slotting unit

1) Touch screen for electronic adjustment

2) Carton box size is manually adjusted.

3) Electronic phase adjustment.

4.Die cutting unit

1) Duramax rubber cushion designed in Taiwan ensures a long useful life.

2) Touch screen for operation and phase adjustment.

3) Mechanical cam structure for precise cuts every time.

4) Electronic phase adjustment.

5.Stack unit

1) Protection devices are installed to protect the operator.

2) The back baffle position is manually adjusted.

3) Chain driven.

4) 1600mm stack height.

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...