Products >> Automatic Flexo Printing Machine for Corrugated Cardboard >> YKW High Definition Flexo Printer -180 Pics/min

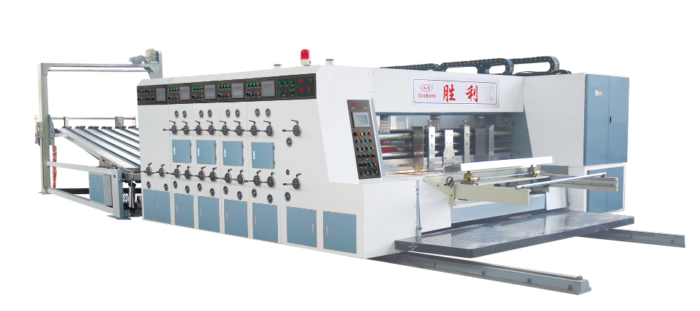

YKW1270 High Definition Flexo Printer with Die Cutter

YKW High Speed Corrugated Carton Flexo Printing Machine is totally designed by Hebei Shengli Carton Equipment Manufacturing Group, is Top-Advanced six colors flexo printing machine for corrugated carton. Integrated with six different color ink and one varnishing unit installed between two independent heating units, YKW High Speed flexo printing machine can achieve the High-Definition Graphics printing, just like offset printing.

| No. | Parameter | Unit | YKW1270x2200 | YKW1270x2500 | YKW1270x2800 |

|---|---|---|---|---|---|

| 1 | Width of inside machine | mm | 2400 | 2700 | 3000 |

| 2 | Maximum production speed | piece/min | 140 kick back 180 lead edge | 140 kick back 180 lead edge | 140 kick back 180 lead edge |

| 3 | Maximum size of feeding paper | mm | 1270×2200 | 1270×2500 | 1270×2800 |

| 4 | Minimum size of feeding paper | mm | 350×700 | 350×700 | 350×700 |

| 5 | Feeding paper by partition | mm | 1600×2200 | 1600×2500 | 1600×2800 |

| 6 | Maximum printing area | mm | 1200×2040 | 1200×2340 | 1200×2640 |

| 7 | Precision of process printing (23/45color) | mm | ±0.5/±0.75 | ±0.5/±0.75 | ±0.5/±0.75 |

| 8 | Thickness of printing paperboard | mm | 3-11 | 3-11 | 3-11 |

| 9 | Thickness of standard printing plate | mm | 7.2 | 7.2 | 7.2 |

| 10 | Minimum grooving space | mm | 290x60x290x60 | 290x60x290x60 | 290x60x290x60 |

| 11 | Maximum depth of slot | mm | 300 | 300 | 300 |

| 12 | printing roller axle circle-oriented | degree | 360 | 360 | 360 |

| 13 | printing roller axle-oriented regulating | mm | ±10 | ±10 | ±10 |

| 14 | Die-cutting thickness | mm | 3-8 | 3-8 | 3-8 |

| 15 | Maximum die-cutting size | mm | 1200×2150 | 1200×2450 | 1200×2750 |

| 16 | Total power (double/three/four/five color) | kw | 40/50/54/63 | 40/50/54/63 | 40/50/54/63 |

| 17 | Size/Double color | mm | 7500x4200x2550 | 7500x4500x2550 | 7500x4800x2550 |

| Size/Three color | mm | 8000x4200x2550 | 8000x4500x2550 | 8000x4800x2550 | |

| Size/Four color | mm | 8500x4200x2550 | 8500x4500x2550 | 8500x4800x2550 | |

| Size/Five color | mm | 9000x4200x2550 | 9000x4500x2550 | 9000x4800x2550 | |

| 18 | Total weight of machine (double/three/four/five colors) | ton | 24/27/30/33 | 27/30/33/36 | 30/33/36/39 |

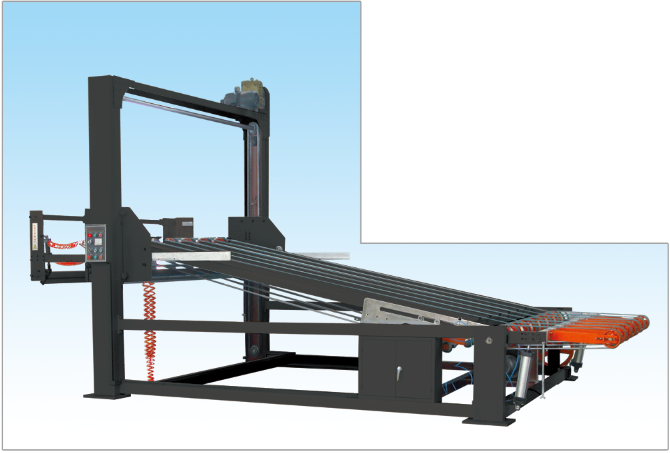

1.Lead edge feeding unit

1.Lead edge feeder system (SUN company of USA)

2.Machine clutch

3.Absorb dust device

5.The operating control switch

The control panel adopts 6 inches touching screen , it can control feeding paperboard department , printing department , die cutting department and it is easy to operate.

6.Automatically zero device.

2.Printing unit

1.Printing roller

2.Printing press roller

3.Ceramic anilox roller ( anilox roller mesh selection according to customer request )

Roller surface adopts advanced spraying ceramic technology , its surface is hardness and smooth after grinding and long using life.

The net point adopts laser grave , the shape is hexagonal honeycomb type and the ink effect is good.

The anilox roller gap adopt manual adjustment with dial shows data.

4.ColorMaster Single Blade System from Sun Automation

Each anilox roller is integrated with one set of colormaster single blade system, which ensures that only ink in the cells is transferred to the plant, achieving the high-definition graphic printing.

5.Upper and under feeding paper roller

The upper roller ,the material is seamless steel tube, it is equipped with four feeding paper wheel

The under roller , surface of the roller adopts grinding and is chromed.

The gap of feeding paper roller adopt manual adjustment , the range is 0-11mm

6.The printing phase adjusting device.

The planet type gear structure.

The printing phase adopt PLC , touching screen and electric numerical 360 degrees adjust (it can adjust both revolving and stopping)

The lateral adjustment range is 20mm with manual adjustment.

The printing plate adopt inverter adjusting the phase . It is quick to zero and adjust the printing plate, the adjusting printing plate precision is high.

7.The ink circulation

It adopts pneumatic type diaphragm pump , supplying effect is steady , it is easy operate and maintain.

The ink strainer , it can clear the impurity .

8.The printing phase fixed device.

Pneumatic type brake device

When the machine separates or adjusting the phase , the brake device can restrict the machine revolving and keep the original gear position.

It adopts seamless steel tube , after two times grinding processing , the surface is hard chromed. It moves steadily.

The pressing wheel gap adopts manual adjustment with dial shows data , the adjusting range is 0-11mm.

The pressing line wheel size is equal with the slotting knife , the pressing line effect is much good.

2.Slotting knife seat device

Electric move transversely : pressing line wheel , the slotting seat adopt vice board link , equipped with the leading slide bar,using the ball screw transmission , can make the pressing line wheel, slotting knife seat move transversely, running smooth and high precision.

Canton box height adjustment : Electric adjustment (PLC control , both static and dynamic can adjust ) , scale shows.

The upper and below shafts adopt seamless steel tube , after two times grinding , surfacer of the roller is hard chromed , move stably.

The slotting knife adopt alloy steel. It also has gone through heat treatment and grinding , the knife shape is saw tooth. Both the rigidity and toughness are very good.The slotting knife width is 7.0mm

The repair edge knife adopt alloy steel and has gone through heat treatment and grinding , the knife is sharp and high precise.

The slotting knife seat gap adopts manual adjustment with dial display.

Planet gear structure.

The slotting phase adopt PLC , touching screen and electric numerical 360 degrees

adjustment (both the machine stopping and running can adjust.)

Stacking department

1.Receiving paper arm

Manual and automatically operation.

The receiving paper arm belt , adjusting the loosen and tension level alone , it will not be influenced by the length of the belt.

The pilling paper speed can adjust according to your needs within certain range.

2.The machine platform up and down

Strong chain drive.

The pilling height is 1600mm.

The machine platform is equipped with the brake function when up and down , so the platform will keep the fixed position and will not glide .

3.The receiving paper baffle.

The pneumatic receiving paper board , when the paper reach the reserve height , the receiving paper board will automatically stretch out and hold the paper.

The back baffle position adopt manual adjustment.

The belt is crease and can prevent the paperboard sliding.

6.The drive gear.

1.Main drive gear

Hebei Shengli Carton Equipment Manufacturing Co.,Ltd is one of the largest Corrugated Carton & Box Making Converting Printing Machines Equipments manufacturers in China, supply high quality machines and good service for corrugated box plants wordwidely. We are specialized at corrugated box carton & cardboard machines . Corrugated sheet making machine, corrugated sheet cutter, boardcard slitter, flexo printing press, box folder & gluer, corrugated cardboard die-cutting machines. Anything you have interested, please contact me : corrugatedboxmachine@hotmail.com

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...